Bullnosing, Cranking & Curving

State of the Art Machinery

GRS has introduced state-of-art machinery to provide accurate Bullnosing, Cranking and Curving of the sheeting to suit the most stringent requirements of Architects and specifiers. Not only does GRS have a static cranking machine, but also a mobile cranking machine for on-site rolling of long length sheets. These details add to the aesthetics of many buildings countrywide, our experts will assist in the design of the details to suit your building.

Cranking of profiled roof sheeting

Certain architectural designs require the Concealed-fix sheet to be curved to achieve the desired effect. Curved sheets are classified into two categories: Cranked sheets and Bullnosed sheets. The curve is obtained by making a series of lateral rib indentations, across the narrow flute (bottom side) of the sheet, pressed in at uniform distances which vary according to the radius requirements, thus causing the sheet to curve to the desired radius. Normally this distance is 25mm.

Bullnosed cranks can be at the end of a sheet or any position along the length of the sheet.

Bullnoses can be manufactured in radii ranging from 300mm to 800mm for bullnoses which are bent through 0º - 135º, larger radii will be classified as a curve. The minimum run-out length from the bullnose to both sides is 75mm.

It is important to identify the critical end of the bullnose to ensure that consistent lengths will be supplied.

The maximum height of centre and off-centre cranks which can be manufactured is 1.5m with a limitation of 10m total sheet length. These limitations are due to handling and transport limitations.

On-site cranking can be done in longer lengths. For guidelines please consult the GRS Technical Service Department.

The calculation of Bullnose Cranking & Curving may only be done by the Customers or GRS Technical Service Department. Before production may get underway, GRS will issue and require a detailed drawing giving all the required information for production. This must be approved by the customer.

Bullnose Cranked sheets can be supplied in standard radii as per the table

Bullnose minimum inside radius

Profile

Forward

Cranking (mm)

Reverse Cranking (mm)

Klip-Tite™

450

N/A

Klip-Lok 700™

450

N/A

Klip-Lok 406™

450

N/A

Klip-Lok 406™

450

N/A

Brownbuilt™

450

N/A

Zip-Tek 420™

1000

N/A

Zip-Tek 440™

N/A

N/A

IBR 686

409

409

IBR 890 (Supa Clad)

450

450

Nu-Rib™

450

450

BR7

450

450

Corrugated

300

300

-

Consideration for road transport has to be taken into account.

-

When allowing for Springing the internal spans for purlins must be 1.5m maximum.

-

Both springing and curving of profiles can result in stresses in the material, resulting in oil canning. Mechanical curving will eliminate the majority of these effects.

-

Care must be taken in checking the structure line of the curve carefully.

Here follows examples of the different types of cranking etc. that are done in the industry.

STANDARD CRANK (EAVES BULLNOSE)

STANDARD CRANK

Standard bullnose cranking is normally done with the narrow flute uppermost and the bend away from the angular inclination.

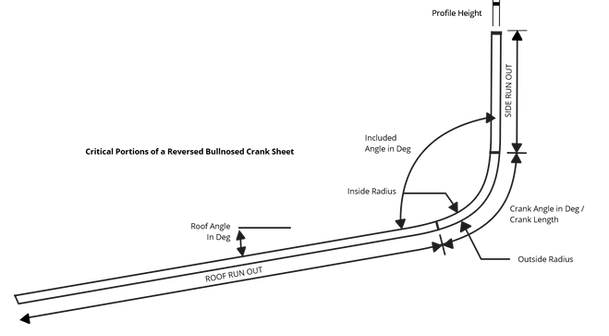

REVERSED CRANK (BULLNOSE)

REVERSE CRANK

Reverse cranking is normally done with the narrow flute downward and the bend into the narrow flute. Applies to pierced fix profiles only.

Cranks can be at the end/ends of a sheet or any position along the length.

CENTRE CRANK

CENTRE CRANK

Centre cranks are made the same way as with either standard bullnoses or reversed bullnoses; however, the cranked section will be in the centre of the sheet length as shown in the drawing below and will follow the roof profile.

Crank Curving, smooth curving & springing of profiled sheets

By increasing the distance between the indentation as with Bullnosing and with manual handling, a larger radius can be achieved. Due to the manual process involved, bullnoses will be priced as curves when the radii exceed 800mm.

The springing of profiled sheets:

For roofs gently curved on elevation, sheets can be sprung on site.

However, extreme caution should be used when attempting this procedure, to prevent buckling or oil canning. Mechanical curving will eliminate the majority of these effects.

The minimum radii for natural site springing on profiled sheets are as follows:

Other types of bullnose cranking done:

Natural springing minimum radius

Profile

Convex (m)

Concave (m)

Klip-Tite™

36

50

Klip-Lok 700™

36

N/A

Klip-Lok 406™

36

40

Brownbuilt™

40

40

Zip-Tek 420™

36

60

Zip-Tek 440™

55

N/A

IBR 686

28

50

IBR 890 (Supa Clad)

36

60

Nu-Rib™

26

55

BR7

18

18

Corrugated

36

50

GRS profiled sheeting can be both Bullnosed & Cranked to meet customers' requirements.

-

Centre Cranks

-

Off-Centre Cranks

-

Forward/Eaves Bullnose

-

Reverse Bullnose

-

Apex Bullnose

-

Double Bullnose

-

Curving can be done to the customer's exact specifications.

Important notes:

-

Purlin spacing and positioning play a critical part in the determination of crank radii, as well as the shape and attributes of the structure on to which the cranked sheets are to be fixed.

-

Remember the minimum radius is always measured on the inside of the profile. For the outside radius just add the profile height.

-

Make sure on which side of the material the colour must be before cranking the sheet. (Broad or Narrow Flute side)

-

Check and confirm critical lengths.